Products

HOME > Products > Construction Grade Plywood > Film Faced Plywood >

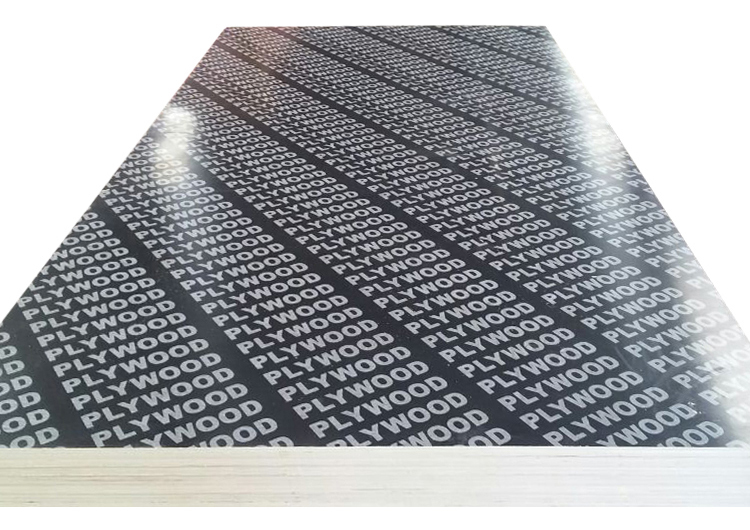

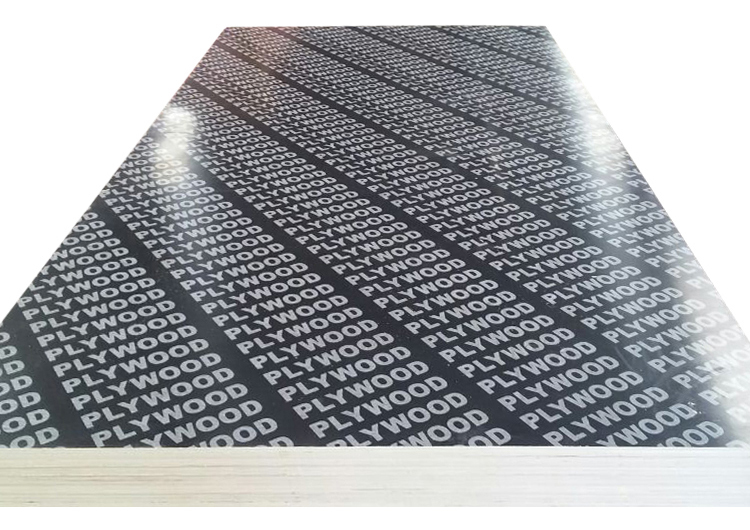

Film faced plywood is also called formwork plywood, shuttering plywoods, concrete form. Film faced plywood is the special plywood with two sides coated with wearable and water proof film. The film is adhesive impregnated paper, which are different from melamine paper overlay, PVC, MDO and HDO. The function of the film is to protect the inside wood from moisture, water, weather and extend the plywood’s service life. Film faced plywood can be used in harsh and outside environment: shuttering plywood, formwork plywood, concrete formwork, floorboard, vehicle building.

1.No wapping, no fracture, not out of shape, it can stay 24 hours in boiling water. 2.Good performance and more turnover use time. 3.It is easy to take off the membrane;Time is only 1/7 of the steel mould. 4.Make the surface of concrete more smooth and beautiful, so it can be easy to make decoration and it also deduct the processing of plastering. 5.This can moderate and contact 30% time for a project. 6.Corrosion resistant and it will not pollute the surface of concrete. 7.It is good to keep performance warm, is favorable to make construction in winter. 8.Products can be made into warping plywood. 9.It is better to nail,saw,drill than bamboo and steel mould, it can be processed into different types.